Which of the following statements is true of process costing? This article provides a comprehensive overview of process costing, its key features, applications, and limitations. By delving into the intricacies of this costing method, readers will gain a thorough understanding of its role in various industries and its significance in cost accounting.

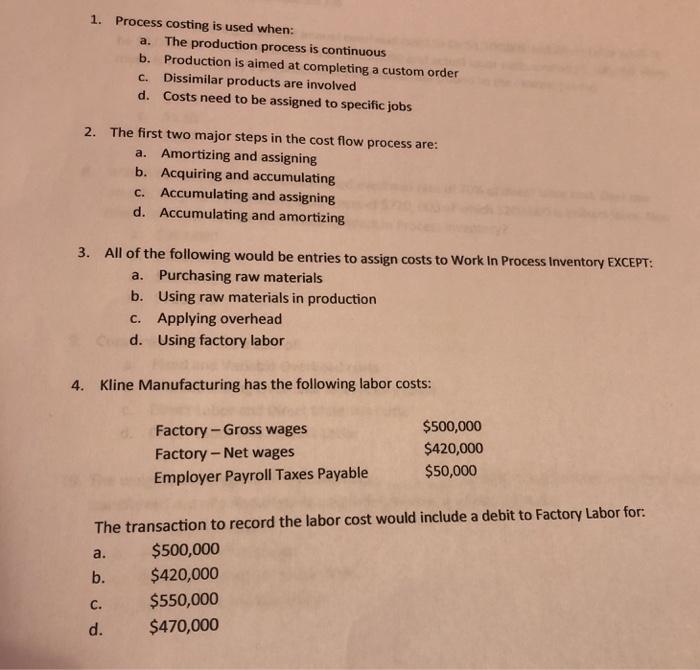

Process costing is a specialized costing method employed in industries with continuous or mass production processes, where units of production are identical and costs are accumulated by process or department rather than by individual units. This method is widely used in industries such as chemical processing, oil refining, and food manufacturing.

1. Definition and Overview of Process Costing

Process costing is a method of accounting used in industries that produce large quantities of identical or similar products through a continuous or repetitive process. Its primary purpose is to assign production costs to each unit of output by accumulating and averaging costs over a specific production period, typically a month or quarter.

Industries that commonly use process costing include food processing, chemical manufacturing, and oil refining, where products are produced in a continuous flow and their costs cannot be easily traced to individual units.

2. Key Features of Process Costing

Process costing is characterized by several unique features:

- Continuous Production:Production occurs in a continuous or repetitive process, making it difficult to identify individual units of production.

- Averaging of Costs:Costs are accumulated and averaged over a production period, resulting in an average cost per unit.

- Equivalent Units:A concept used to adjust for the fact that some units may not be fully completed at the end of the period. Equivalent units represent the number of fully completed units that could have been produced using the costs incurred during the period.

3. Steps Involved in Process Costing

Process costing involves the following steps:

- Data Gathering:Collect data on production quantities, costs incurred, and equivalent units.

- Cost Assignment:Assign costs to processes and products based on the equivalent units.

- Unit Cost Calculation:Calculate the unit cost by dividing the total costs by the equivalent units.

4. Methods for Assigning Costs

Various methods can be used to assign costs to processes and products:

- Weighted Average Method:Averages costs over the entire production period.

- FIFO (First-In, First-Out):Assumes that the earliest costs incurred are assigned first.

- LIFO (Last-In, First-Out):Assumes that the latest costs incurred are assigned first.

Each method has its advantages and disadvantages, and the choice depends on the specific industry and cost flow assumptions.

5. Applications of Process Costing

Process costing has various applications:

- Inventory Valuation:Determine the cost of inventory at different stages of production.

- Cost Control:Identify areas of inefficiencies and cost reduction opportunities.

- Decision-Making:Provide information for pricing, product mix, and production planning decisions.

6. Limitations and Challenges of Process Costing: Which Of The Following Statements Is True Of Process Costing

Process costing has certain limitations:

- Accuracy Issues:Costs are averaged over a period, which may not accurately reflect the cost of individual units.

- Assumption of Uniform Production:Assumes that production occurs at a uniform rate, which may not always be the case.

To mitigate these limitations, strategies such as periodic cost reconciliation and statistical sampling can be employed.

FAQ

What is the primary purpose of process costing?

Process costing aims to assign costs to units of production in continuous or mass production processes where individual units are indistinguishable.

What are the key features of process costing?

Process costing involves continuous production, averaging of costs, and the use of equivalent units to account for partially completed units.

What are the advantages of process costing?

Process costing provides accurate cost allocation, simplifies inventory valuation, and supports decision-making in continuous production environments.

What are the challenges associated with process costing?

Process costing may face challenges in ensuring accuracy due to the assumption of uniform production and potential errors in cost assignment.